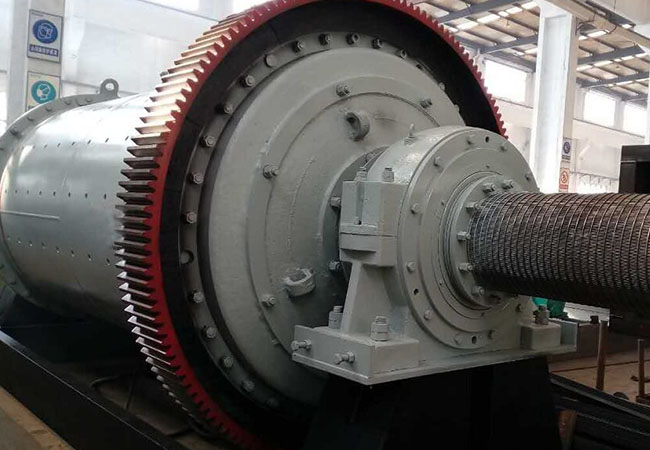

MINERAL GRINDING & CLASSIFYING EQUIPMENT

Energy Saving Ball Mill

- Product ID:MINERAL GRINDING & CLASSIFYING EQUIPMENT

- Phone: +86-371-55091029

- Tel: +86 18538798892

- Email: sale@zzddjt.com

Introduction

Ball mill is a key mineral processing machine for milling the materials into powders after they are crushed, it has wet and dry type.

Processing Materials

Gold, silver, lead, zinc, copper, molybdenum, iron, lead, manganese, tungsten, cement, ceramics, barite, bauxite, limestone, gypsum, calcium carbonate, coal, graphite, feldspar, potash feldspar, phosphorus ore, fluorite, clay and some other materials.

Application Range

It is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries.

Advantages and Characteristics

It is suitable for grinding material with high hardness.

It is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

Adopt overall frame, which makes it easy for construction,installation and adjustment.

Large discharge opening, high capacity.

Working Principle

This machine is a horizontal type cylinder rotary device and outside the cylinder there is drive gear which drives the cylinder to rotate during the working process. Materials spirally and evenly go into the first cabin of the grinding machine through the feeding hollow shaft from the feeding device, and inside the first cabin, there are ladder lining boards or ripple lining board in which there are many steel balls with different specifications. The cylinder rotates and produces eccentric force to bring the steel balls to a certain height, and then the steel balls will fall down to impact and grind the materials. After being coarsely ground in the first cabin, the materials will go through the single-layer partition board and into the secondary cabin in which there are flat lining board, and in the lining board there are steel balls to further grind the materials. Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding proces

1. Bush bearing is replaced by rolling bearing, friction resistance being greatly lowered down,easy to start and energy saving.it's energy is lower 10%-15% than the old one.

2. The capacity is larger: for the outlet disk and the checked liner are adopted,the capacity is higher 20% than the cone ball mill.

3. Easy to construct: for one-fiece frame is used, it's easy for the facilitating and equipment installation.

| Wet ball mills | |||||||||||

| Model | barrel | Motor | boundary dimension | Effective volume(m3) | Max loading ball(t) | weight(kg) | |||||

| digmeter(mm) | length(mm) | speed(r/min) | Model | Power(kw) | length | width | height | ||||

| (mm) | (mm) | (mm) | |||||||||

| MQG 0918 | 900 | 1800 | 39.2 | Y225M-8 | 22 | 4196 | 2336 | 2015 | 0.9 | 1.92 | 5340 |

| MQG 1212 | 1200 | 1200 | 31.3 | Y250M-8 | 30 | 4500 | 2104 | 1733 | 1.1 | 2.4 | 11438 |

| MQG 1224 | 1200 | 2400 | 31.3 | Y280M-8 | 45 | 5764 | 2104 | 1733 | 2.4 | 4.6 | 13200 |

| MQG 1515 | 1500 | 1500 | 30.9 | JR115-8 | 60 | 6094 | 2743 | 2170 | 2.5 | 5 | 13120 |

| MQG 1530 | 1500 | 3000 | 30.9 | JR117-8 | 80 | 6800 | 2743 | 2170 | 5.08 | 8.6 | 19166 |

| MQG 1545 | 1500 | 4500 | 30.9 | JR127-8 | 130 | 9085 | 3091 | 2170 | 6.57 | 11.3 | 22147 |

| MQG 2122 | 2100 | 2200 | 24.05 | JR128-8 | 155 | 7750 | 4450 | 3533 | 6.6 | 16 | 42500 |

| MQG 2130 | 2100 | 3000 | 24.05 | JR137-8 | 210 | 8330 | 4450 | 3533 | 9 | 20 | 44260 |

| MQG 2145 | 2100 | 4500 | 24.05 | JR138-8 | 245 | 9933 | 4450 | 3533 | 13 | 23.5 | 50348 |

| MQG 2430 | 2400 | 3000 | 22.5 | JR138-8A | 280 | 8823 | 5113 | 3894 | 12.1 | 22.5 | 58328 |

| MQG 2436 | 2400 | 3600 | 22.5 | JR138-8B | 320 | 9455 | 5113 | 3894 | 14.5 | 26 | 61308 |

| MQG 2727 | 2700 | 2700 | 21.6 | JR138-8B | 320 | 8643 | 5722 | 4674 | 15.3 | 30 | 83145 |

| MQG 2736 | 2700 | 3600 | 21.6 | JR1510-8 | 400 | 10463 | 5942 | 4674 | 18.4 | 36 | 89120 |

| MQG 2745 | 2700 | 4500 | 21.6 | TDMK500-32 | 500 | 11471 | 5907 | 4674 | 23 | 45 | 109318 |

| MQG 3236 | 3200 | 3600 | 18.5 | TDMK630-36 | 630 | 12442 | 7030 | 5150 | 25.6 | 51 | 144241 |

| MQG 3245 | 3200 | 4500 | 18.5 | TDMK800-36 | 800 | 13975 | 7030 | 5150 | 32.8 | 65 | 153390 |

| MQG 3639 | 3600 | 3900 | 17.3 | TDMK1000-40 | 1000 | 15000 | 7200 | 6300 | 36.2 | 75 | 168800 |

| MQG 3645 | 3600 | 4500 | 17.3 | TDMK1250-40 | 1250 | 15200 | 7750 | 6300 | 41.8 | 90 | 179900 |

| MQG 3650 | 3600 | 5000 | 17.3 | TDMK1400-40 | 1400 | 17600 | 7750 | 6300 | 46.4 | 96 | 183000 |

| MQG 3660 | 3600 | 6000 | 17.3 | TDMK1600-40 | 1600 | 17000 | 8800 | 6500 | 55.7 | 120 | 204000 |

| MQG 4060 | 4000 | 6000 | 16.2 | TDMK1700-30 | 1700 | 17400 | 9500 | 7600 | 69.8 | 137 | 214000 |

| MQG 4560 | 4500 | 6000 | 15..3 | TDMK2300-30 | 2300 | 17800 | 10500 | 7600 | 87 | 158 | 294000 |

PRODUCTS

CONTACT US

Phone: +86-371-55091029

Tel / WhatsApp: +86 18538798892

Add: Zhengzhou Dongding Machinery Co., Ltd