CRUSHING & SCREENING EQUIPMENT

Four Rollers Crusher

- Product ID:CRUSHING & SCREENING EQUIPMENT

- Phone: +86-371-55091029

- Tel: +86 18538798892

- Email: sale@zzddjt.com

Interested? Leave a meassge for Tech and Price.

Four Tooth Roller Crusher Introduction

Four tooth roller crusher has four abrasive rollers, usually the top two are toothed rollers, and the below two are overlay welding or flat rollers. Range of the discharge is 2-30mm, the feed size less than 700mm.

It is suitable for medium crushing and coarse crushing. Such as thermal power plant’s fluidized bed boiler, the breaking of ordinary steam coal, fertilizer raw material crushing of fertilizer plant, solar industry crushes waste glass tube, or at the similar occasion.

It is suitable for medium crushing and coarse crushing. Such as thermal power plant’s fluidized bed boiler, the breaking of ordinary steam coal, fertilizer raw material crushing of fertilizer plant, solar industry crushes waste glass tube, or at the similar occasion.

If the compression strength is more than 180 Mpa, you can choose extra-heavy model. According to different requirement of consumers, the driving mode is divided into triangular belt and shaft coupling. The driving power can be electric motor or diesel engine.

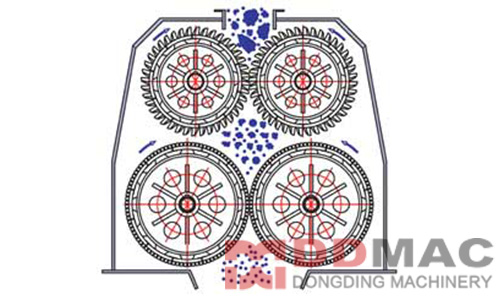

Four Teeth Roller CrusherWorking Principle

Four tooth roller crusher is configured with four high-strength wear-resistant grinding rollers. The rollers rotate relatively to make high pressure to crush materials.

The material enter into the space between the two rollers and firstly are extruded, pressed and sheared (thick broken). Then the materials enter to the next two rotating rollers.

Here it is extruded, cut and grinded to the required size, sent to the transport equipment.

The material enter into the space between the two rollers and firstly are extruded, pressed and sheared (thick broken). Then the materials enter to the next two rotating rollers.

Here it is extruded, cut and grinded to the required size, sent to the transport equipment.

Four Rollers Crusher Characteristics

1. Adopting wear-resisting chromium molybdenum copper alloy,the rollers heat treated process, service life reach 2000-8000 hours(according to the hardness of the raw material).

1. Adopting wear-resisting chromium molybdenum copper alloy,the rollers heat treated process, service life reach 2000-8000 hours(according to the hardness of the raw material).

2.If the material is too hard or unbreakable materials, the working roller will draw back automatically by the force of the spring or hydraulic system to protect the machine from being damaged.

3.Gap between the rollers adjustable,capacity will be changed accordingly.

4. This crusher uses the best bearing produced, the service life of the bearing more longer. The inner and outside of the bearing are both double sealed, so the lubrication oil can be added in a long period.

5. This crusher uses no power distributor, the materials will be evenly distributed into the crusher, to ensure good output size and protect the roller surface from being worn down unevenly.

6. Crusher equipped with motorless scraper. When the raw material has high moisture content, it can avoid to affect the output size and avoid sticking the roller or blocking the machine.

7. It runs in different speed, the rollers do cleaning for each other to avoid the raw materials caking.

8. Crusher features reliable operation, low failure rate, low noise and low maintenance cost.

Four Roller Crusher Technical Parameter

| Model |

Feed Size (мм) |

Output Size (мм) |

Capacity (t/h) |

Motor Power (KW) |

| 4PG0404Ⅱ | <20 | 0.3-10 | 2-30 | 2×7.5 |

| 4PG0605Ⅱ | <30 | 0.3-15 | 5-60 | 2×22 |

| 4PG0806Ⅱ | <40 | 0.3-20 | 8-90 | 2×30 |

| 4PG0809Ⅱ | <60 | 0.3-20 | 12-120 | 2×37 |

| 4PG0812Ⅱ | <60 | 0.3-20 | 20-180 | 2×45 |

| 4PG1012Ⅱ | <80 | 0.3-30 | 30-220 | 2×55 |

| 4PG1212Ⅱ | <90 | 0.3-50 | 45-320 | 2×75 |

| 4PG1216Ⅱ | <90 | 0.3-50 | 55-400 | 2×90 |

| 4PG1218Ⅱ | <90 | 0.3-50 | 70-500 | 2×110 |

PREVIOUS:Symons Cone Crusher NEXT:Hydraulic Cone Crusher

PRODUCTS

CONTACT US

Phone: +86-371-55091029

Tel / WhatsApp: +86 18538798892

Add: Zhengzhou Dongding Machinery Co., Ltd